Basic information

MicroStep, spol. s r.o.

Manufacturing of CNC cutting machines, control systems and CAM software

Vajnorská 158

831 04 Bratislava

Slovakia

Mobile: +421 918 799 036

E-mail: sales@microstep.sk

Web: www.microstep.eu

ID: 00603015

VAT / Tax ID: SK2020418994

Customer: MicroStep, spol. s r.o.

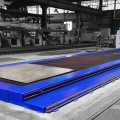

Complex CNC Cutting Machines

• cutting of sheets, pipes, profiles, domes, elbows

• combination of technologies on one machine

• wide range of additional accessories

• material flow automation

• CAPP applications for production management

• CAM software

• robotic applications

• PLASMA

• LASER

• OXYFUEL

• WATERJET

• DRILLING

• TAPPING

• MARKING

MicroStep - Váš partner pre rezanie a automatizáciu

Multi-functional CNC cutting Machines

Since its inception in 1991, the company MicroStep, spol. s r. o. has been involved in design and manufacturing of CNC cutting machines equipped with plasma, laser, oxyfuel and waterjet technologies as well as routing and drilling machines. Over the years, the company has become one of the leading suppliers of cutting equipment and has supplied more than 3,000 machines worldwide in cooperation with strong channel partners spread in 58 countries. More than 30 % of the company’s products are complex machines which require continuous development and research for new, innovative technical solutions. Today, MicroStep is able to offer the full range of contemporarily used cutting technologies along with a great variety of additional equipment and software for drilling, tapping, countersinking, laser marking, inkjet marking, micropercussion marking, process synchronization (scanners, CCD cameras) and material handling. As a producer of not only machine mechanics but also control systems and CAM software the company delivers solutions that perfectly fit actual customers’ demands and are future-proof with respect to machine extensions in size and additional technologies.

Moreover, MicroStep machines can process several types of material including sheets, pipes, profiles, domes and elbows while implementing advanced processes such as automatic welding seam preparation. All of MicroStep machines are operated by iMSNC®, a multi-tasking PC-based control system developed and produced in-house.

Our goal is to provide solutions that improve everyday job in the factories – assure higher precision, minimize downtimes, assure more convenient and more effective operation and easier maintenance.

We achieve this through higher automation levels, interconnection of control systems, CAM software and ERP systems at customer´s site (our production management software MPM has already found its application in several enterprises in Europe and Asia – either integrated into customer’s ERP system or standalone), and through development of more sophisticated equipment. And our customers obviously agree: e.g. our patent pending technology ACTG – a system that reduces the setup time of bevel head from hours to a couple of minutes – has already been delivered with more than 450 systems and is proving its high relevancy in daily operations worldwide.

The cutting equipment is going through a massive change worldwide. New systems bring new possibilities to cutting processes so there is a continuous need for integration of these technologies into CNC machines. This puts new demands on machine mechanics and controls. Thanks to the continuous and effective R&D in the fields of new mechanical components, electronic modules and control systems software, MicroStep has been able to adapt quickly to the new trends. In addition to our own R&D base we work closely with departments of the Slovak Technical University in Bratislava and the Institute of Materials & Machine Mechanics of the Slovak Academy of Sciences on utilization of latest achievements in design and control of machinery. Thanks to our constant search for innovations we have also quickly become a valued partner for many renowned suppliers.

Published: 12. 12. 2025